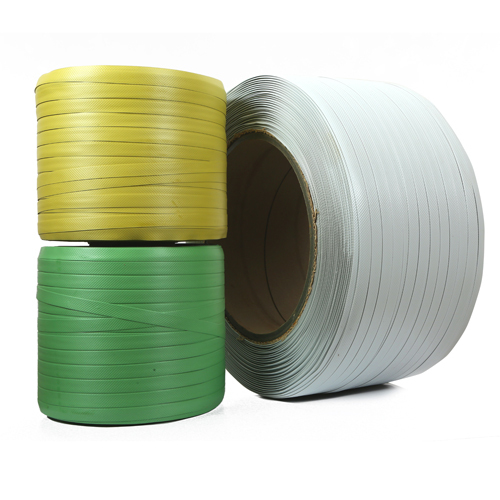

PACKERS PLASTIC BOX STRAP

Product Details:

- Material PP

- Size 12 mm

- Color Yellow & green

- Width 0.3 mm Millimeter (mm)

- Usage BOX PACKING

- Application Pacakaging

- Click to View more

X

PACKERS PLASTIC BOX STRAP Price And Quantity

- 1 Container

PACKERS PLASTIC BOX STRAP Product Specifications

- Pacakaging

- PP

- BOX PACKING

- 0.3 mm Millimeter (mm)

- Yellow & green

- 12 mm

PACKERS PLASTIC BOX STRAP Trade Information

- Mundra

- Cash Advance (CA) Cash in Advance (CID)

- 5000 Container Per Month

- 10 Days

- Yes

- Free samples are available

- All India

Product Description

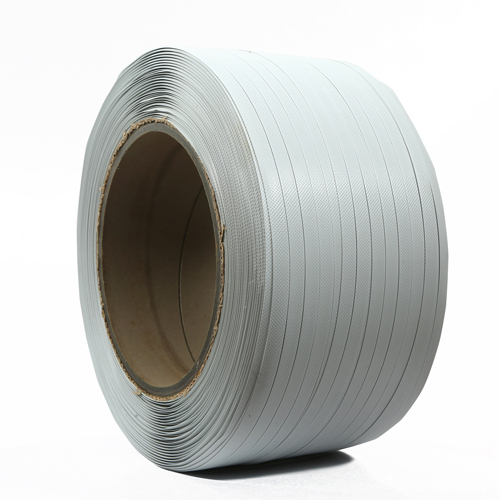

Polypropylene (PP) strapping is one of the most common types of strapping and comes in a variety of tensile strengths, widths, and core sizes depending on your application.

Its almost always embossed, giving it additional strength and texture for better friction. Embossing also significantly reduces dust created during the strapping process.

Polypropylene strapping can be applied manually with buckles or hand tools up to fully automated strapping machines.

PP strapping stretches around 25% when applying, however, it recovers about 10% back shortly after. As a package or pallet settles, the strap will retain some tension. Polyester and steel will not recover as your package/pallet settles.

Unless otherwise formulated, plain PP strap can be sensitive to UV light degradation and is sometimes negatively impacted by elevated temperatures. By selecting the proper formulation of PP strapping with your supplier, you won't have to worry about these downsides.

Enter Buying Requirement Details